The customer wasn’t pleased. I had obviously done something wrong. I showed them the paperwork with the specifications showing that the input to the dimmers was to be 20 amps. They insisted that their electrician knew better than I did.

Well, it was bound to happen eventually. As far as we here at PluginCars.com know, these are the first pics ever seen of what the internal guts of an AeroVironment-branded Nissan LEAF charging station look like.

This is true in a certain temperature range, I think between 70 and 90% of their nominal power. And in spite of that there are so many lamps with halogen bulbs, which are fitted with dimmer circuits. And you know why? Because the bulbs are very cheap, so nobody cares ![]() And they are often used as heating elements: in a professional reflow oven (3000,- euro class) and in laser printers. But in the end I think for the heated print bed you do NOT want a radiative heat source, it complicates the things

And they are often used as heating elements: in a professional reflow oven (3000,- euro class) and in laser printers. But in the end I think for the heated print bed you do NOT want a radiative heat source, it complicates the things

Not really clear but good point. I met an electrician who told me : ‘230VAC is not dangerous, I’m getting shocked a lot, it really hurts when its 400VAC. Oh by the way, I have to get an appointment for my heart !’

[Nick Sayer] falls into the “would rather build it than buy it” category. This particular project is a clone of a fast electric vehicle charger. There are commercially available versions sold under the Quick 220 brand name. The idea is that for fast charging, some electric vehicles call for a 240V outlet and Americans without electric cars often don’t have one. If they do it’s for an appliance like a stove or clothes dryer and probably not found in the garage.

I don’t know if the heat is high enough but mirror heating pads can be quite small and put under a sheet of glass would be quite effective.

Sure I expect my line voltages to vary especially given that the actual spec for my line voltage (UK) is 230V +10%/-6% – my nominal voltage where I’m sitting is around 242V and I’ve seen it go as high as 252 and as low as 220.

I like the idea, but you don’t need a 3D printer for this. Just use conductive strips or good ol’ fashioned wire.

253V above. The 3% voltage reduction equalled 5% of the load and 6% voltage reduction 10% of the load I seem to remember. Over 15 years ago.

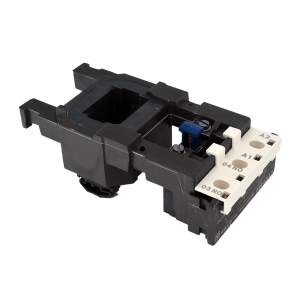

One possibility (on contactors) is to have a split pole with a copper ring one one half. This is similar to a shaded pole motor. The current which is induced in the copper ring (shorted winding) is out of phase with the current in the main winding and smooths out the zero crossings. Another possibility, mostly used on valves, is to rely on the inertia of the core, here the dampening effect of the fluid also helps. The device is just not fast enough to follow the 100Hz (or 120Hz in some oversea countries) ripple.

Comparable relay product datasheets from Omron suggest that without appropriate heatsinking, the current limit should be in the range of 4A to 7A.

Prior circuit. The OP says in the thread that he puts 8 foot cords on his so he doesn’t need to use an extension cord. Personally I’d go longer, also I’d keep a common “3-lamp” outlet tester handy.

Google’s Night Sight for Pixel phones will amaze you | 25 Amp Circuit Breaker Related Video:

Adhering into the basic principle of "quality, assistance, effectiveness and growth", we have attained trusts and praises from domestic and worldwide client for Electrical Relay Contactor , Schneider Relays And Contactors , Contactor With Overload Relay , Our team knows well the market demands in different countries, and is capable of supplying suitable quality products at the best prices to different markets. Our company has already set up a professional, creative and responsible team to develop clients with the multi-win principle.