The place to start when talking about mains-voltage equipment is your bench. We realise you’ll probably be working at your kitchen table or wherever you happen to be, but it’s best to start an article like this with a baseline, of what you really should have when doing this stuff. There are three things we’d consider essential in the mains power system on a mains-voltage bench. An isolation transformer to power the item you are working on if it needs a mains supply, a residual current circuit breaker for the rest of your mains supplies, and an emergency isolation switch for all bench power.

Heck, as I said, when I have needed to do this in the past I just used a multimeter, a terminal block, and no relaying whatsoever (ah, being perhaps complacent “qualified personnel”, eh?)

Nissan has said that most people who get their LEAF charging stations installed by AeroVironment will pay around $2,200 to $2,500 in hardware, permits and labor—$750 of which is for the actual charge station hardware. While the pictures are interesting in-and-of-themselves for those of us that care about what happens under the hood of all of our equipment, the bigger question the pictures bring up is what, exactly, you’re paying for when you plunk down your $750 for the hardware.

The MOT cores are welded to the head, so they’re not coming loose without shearing. The sole purpose of the epoxy would be to keep the coils mounted to the cores (as well as keeping them free of damaging debris that would short the coils.) The only force the epoxy sees is from the eddy currents trying to push the coils away from the core (or vice-versa.) That energy then becomes the electromagnetic force that gets “transferred” to the ferrous cores – that are welded to the head. Since the force from the eddy current is fairly weak, there’s an low extremely low risk for such a failure. Not impossible, but it would take a catastrophic failure.

The ESD protective wrist strap should not tie you to a hard ground, it usually has a 1Meg resistor included, just for this reason. But perhaps not every cheap chinese one has?

My grandmother had a set of glass topped buffet serving tables where the glass top had a foil element sandwiched between the glass layers. They plugged right into the wall. No components other than the heating element, line cord, and a neon bulb to remind you it was plugged in. The element terminated with a couple of fused in copper rods threaded to take nuts. Got too hot to comfortably touch, but warm enough to keep your food hot. It should be within the capabilities of a glass/ceramics hobbiest with a kiln to sandwich a foil element between two pieces of glass and fuse the sandwich together.

The theory side of PCB creepage clearnesses is useless because it assumes that there is one constant voltage that the circuit will run at when in reality it’s an over voltage event that usually causes failure, but here are the basics anyway.

We first saw this feature in Sony’s DSC-TX1 and DSC-WX1 in mid-2009. Since then, it’s been mimicked by other manufacturers, but none seem to do it as well as Sony. In Handheld Twilight mode, the camera captures up to 6 shots in rapid succession, micro-aligns them with each other, and then adds them all together. The net result is that you can hand-hold ridiculously long exposures and still get sharp results, with very low image noise to boot. Combine this with Sony’s SteadyShot image stabilization and sharp handheld photos at half-second exposure times are feasible.

I’m certainly pleased the US Air Force along with the wind turbine industry taught me just a few skill sets in getting that Level 2 service expeditiously installed.

Heat damage from increased resistance is pernicious. P = I^2 * R. At 24 amps, a resistance of a mere tenth of an ohm is 57 watts – almost twice as much as a pencil soldering iron! That’s why it’s important to get those crimps done right and inspect them frequently for signs of degradation. I will readily concede that I am not equal to a manufacturer in terms of consistency and reliability of crimps, even with a ratcheting tool. The only way I can make up for that is keeping an eye on things to catch early degenerative changes before things get out of hand. Part and parcel of building high powered electrical equipment by hand is being ever vigilant when using it.

3-phase installations like industrial facilities and some apartments are fed with 208V 3-phase, which provide three phases of 120V to neutral, or 208V phase-to-phase.

idk, anytime I’ve been shocked on the job I tend to immediately pull back – usually any screwdriver I have in my hands goes flying, and hopefully its not towards me or anyone else’s face. Which is why I use all 1000v insulated screwdrivers now. Better sorry than safe, kill two stones with one bird. You can definitely “feel” the alternating current.

How Intel’s 9th Gen chips show the way forward after Moore’s Law | Lrd12 Overload Relay Related Video:

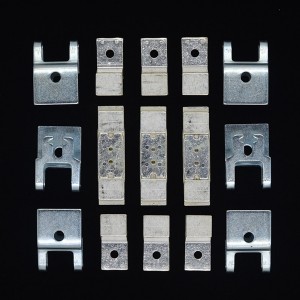

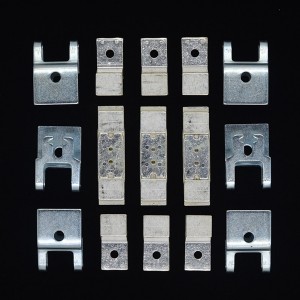

To meet the customers' over-expected satisfaction , we have our strong team to provide our best overall service which includes marketing, sales, designing, production, quality controlling, packing, warehousing and logistics for Lr2-D13 Overload Relay , Contactor Lc1d25 , Is Contacts Kit , Our company will adhere to "Quality first, , perfection forever, people-oriented , technology innovation"business philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant professional knowledge, to develop advanced production equipment and production process , to create the first-call quality products, reasonable price , high quality of service , quick delivery , to give you create new value .